Preparation

Chinsunboard | Preparation of Materials:

In order to achieve a good result the panels must be installed on a stiff, strong, flat & level construction, we know the following instructions:

Before You Begin

Receipt of the Material

Any damages or deviations must be immediately specified IN WRITING on the bill of lading when the delivery driver is still present. A copy of the bill of lading, with any remarks, must be submitted to the driver at the time of delivery.

Access to the job site must be such that deliveries can be made by a full 18 wheel flat-bed, or an enclosed tractor trailer. When placing the order please specify if you are able to unload an enclosed trailer, or if you will require a flat-bed delivery.

The job site must have access to accommodate an 18 wheel flat bed or enclosed tractor trailer. When placing an order please specify if you are able to unload an enclosed trailer or flat bed delivery. Smaller trucks can be arranged if needed.

It is the recipient’s responsibility for unloading the material, & provisions must be arranged prior to the delivery. The delivery driver is not allowed to assist in unloading the material. The delivery driver will call 24 hours before making the drop to schedule the delivery.

Inspection of the Material

It is the recipient’s responsibility that all the materials are not damaged & in accordance with the order submitted. Any damages must be immediately documented in writing on the bill of lading while the delivery company employee is still present. Photos are required at that time for further documentation of damage. CBF must be notified & provided with a copy of the bill of lading the same day as the delivery. Materials may only be returned after the freight claim is submitted.

Storing the Material

The material must be kept in a dry, well ventilated area, raised off the ground, & on a dry level surface at all times. Extended storage (more than two weeks) must take place in a dry ventilated building, & the plastic wrap should be removed. The panels must always be stored raised off the ground with supports at a maximum of 19”, & always stacked with the edges directly over each other. The accessories should also be protected against dirt & precipitation. Flat panels that get wet due to precipitation or condensation will precipitate calcium/efflorescence, & will result in permanent damage that would not occur when properly stored or in proper use. If the boards do get damp when stacked, individually place the panels on their edge to ensure rapid drying & good ventilation. NEVER cut, drill, or install when the material is damp or in damp conditions.

Handl the Material

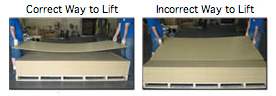

Lift

The sheets must be lifted, not dragged off the stack.

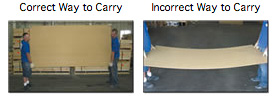

Carry

The sheets must be carried by two people and by the edge.

The material must be handled with care as to not damage the face, the corners or the edges. While handling the material you must also take care as to protect the panels against dirt & moisture as this will damage the material. Do not stack wet or dirty boards, as this will result in permanent damage that would not occur if properly handled.

Accessories

Accessories Needed for Installation

Wind & Water Barrier*

There must be a wind & water barrier behind the facade cladding that is designed to make the structure impervious to the weather & the wind. Water will penetrate our facade cladding so it is extremely important to ensure that your wall is 100% waterproofed by the membrane. This product should be a breathable waterproof membrane to protect the substrate from damaging moisture from the weather, as well as allowing the building to breathe and the condensation within the structure to escape. *Required and supplied by CBF Inc.

* The maximum length of any furring strip is 10ft.

* NEVER use a combination of wood & steel furring.

* It is the client’s responsibility to choose the correct wood product.

*The use of treated lumber is not recommended.

* Specific static calculations must comply with local regulations.

* This Item is not supplied by CBF.

Supports / Furring Strips*

Regardless of the construction, our cladding sheets must be fastened to supports of sectional wood or steel. The depth of the strips must create aminimum3/4” hollow air grip from back of our panels to the substrate.

Steel Dimensions

When using steel furring you may use hat channels, z-furring, or a combination of the two. The steel must be 16 or 18 guage.

Wood Dimensions

When using wood we recommend painting the lumber black with an exterior grade paint or wrapping it with the weather barrier. This will not only help to preserve the wood, it will also hide the wood in the horizontal gaps.

EPDM Rubber Strips**

DIMENSIONS

3 ½” x ⅛”

1 ¼” x ⅛”

The EPDM rubber strips must always be used on the supporting structure of wood or steel furring strips, & are applied as a direct base for our material. You may staple or use a spray adhesive to attach the EPDM rubber strips to the furring strips. These strips not only help to protect the furring, but also aid in the movement of our material. The wider strips are applied on the furring at the vertical joints & the narrower strips are applied on the furring in the field of the material. ** This item is supplied by CBF.

Stainless Steel Screws**

The panels are secured to the supporting structure using exposed stainless steel pan head screws. The screw spacing will be determined by the furring style used. Please refer to the installation instructions on page 13 & 14. The screws cannot be countersunk because the panels need movement to succeed.

You will be supplied with one driver per every 250 screws. All our screws for steel are self drilling.

DO NOT OVERTIGHTEN THE SCREWS

Over tightening screws will restrict the movement of the panels, which will crack the panels.

General Preparation

Attention to Details

In order to achieve a good result the panels must be installed on a stiff, strong, flat & level construction. The wall’s stability must be ensured without help from our products. Attention to detail is of MAJOR importance, so it is therefore important that the joints & connections of the cladding are solved and completed with precision & care.

Since our products will move when the climate changes, they may bend +/- 1/4”.

Ventilated Construction

Our facade cladding must always be installed as a ventilated construction with the outermost cladding open in order to allow ventilation of an underlaying cavity. There must be a minimum 3/4” hollow air gap between the substrate & the back of our panels. You must also allow for a 5/16” gap between sheets in both the vertical & horizontal joints, as well as a 3/4” gap at the very bottom of the wall & at the soffit/cap.

This ventilation is an upgoing air flow from the bottom of the wall to the soffit/cap & this air gap is not to be blocked at any point. There must also be a minimum 1/2” through going air gap on each height between floors (a 1/2” gap between the furring strips).

The ventilation equalizes the changes in pressures, which can be caused by gusts of wind, climate change, or drying of the panels, as well as ensuring humidity & condensation from both inside and outside the structure is able to escape.

Safety

Inhalation:Acute over-exposure to dust may cause mild irritation & inflammation of the respiratory tract & organs. Use approved respiratory equipment when airborne dust is present. We advise the use of a dust extractor & a mask when cutting with power tools. If irritation occurs, get into fresh air. If condition persists, seek medical advise.

Eye Contact:You may experience a mild discomfort of the eyes caused by the dust. Always wear safety goggles when cutting or drilling the material. If an irritation occurs, flush with plenty of fresh water, & seek medical attention if condition persists.

Skin Contact:Prolonged contact may cause a mild irritation. You should always wear gloves when handling the material. If an irratation occurs, wash hands thoroughly with water.

Although our products contain no asbestos, you should choose a working method which minimizes dust during installation.

Fabricating the Material

CBF will fabricate the order per your cut list. Our facilities are equipped with two industrial stone saws. Our fabrication is done with a 20” segmented diamond blade to ensure accurate lines and measurements. This blade leaves a sharp edge with minimal chipping. The correct diamond blades and drill bits are available for purchase from our facility. The fabrication must be done with the finished side facing up. If larger holes are needed use a diamond tipped hole saw. For cuts that don’t require a sharp edge, jigsaws with a carbide tip are required. It is imperative to only work with dry material and in dry conditions. Working with damp panels or in damp conditions will cause dust from the fabrication to “burn” into the panel and will leave permanent stains. This will void any warranty claims. Do NOT use adhesive tapes on the face of the panels.

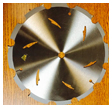

Poly-Crystalline Diamond Blade

Poly-Crystalline Diamond Blade

For a sharp, clean edge the material can be easily cut using a table saw or a high speed circular saw with a Poly-Crystalline Diamond tooth blade. Cutting is done from the front side of the material to protect the surface from damage. This blade has a thin kerf for fast cuts with less dust. Do not use adhesive tapes to mark your cut lines.

Diamond Tipped Hole Saw

Diamond Tipped Hole Saw

Holes requiring a sharp edge may be cut with a diamond tipped hole saw, or by drilling a series of holes no more than 1/4″ apart.

Carbide Tipped Jigsaw Blade

For cuts that do not require a sharp edge a jigsaw with a carbide tipped blade may be used.

When the material is cut the edges must be resealed. If CBF cuts the material we will reseal the edges. If the edges are cut in the field, we will supply the resealing product.

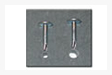

Pre-Drilling the Material

The holes must be pre-drilled on-site from the finished side of the material facing up using carbide tipped drill bits. (CBF can supply the drill bits.) The holes must be drilled larger than the shaft of the screw to allow for movement of the panel.

Only work with dry material & in dry conditions. Working with damp material or in damp conditions will cause the dust to permanent “burn” into the material & leave permanent stains.

Steel Furring

Steel Furring

When using steel furring strips there must be one fixed point near the center of the board with a 7/32” drill bit. The other dilation points will be oversized using a 9/32” drill bit.

Wood Furring

Wood Furring

When using wood furring strips you will only have dilation points using a 9/32” drill bit, which are all oversized.

Completion of Work

When the installation is complete check to ensure the cladding is clean and without damage, defects, or omissions.

When the installation is complete check to ensure the cladding is clean and without damage, defects, or omissions. It is important that you remove any dust from the face of the panels before installing to avoid the dust from permanently burning into the material.

Please contact CBF if further cleaning instructions are needed.

(Dust from cutting the edge)